I’ve certainly been attempting to revert into more historic pre ww1 type housing style recently. Is this partly just self serving to appeal to on trend house shoppers, to make it easier to permit and raise less objections, or to integrate better into the existing character of the area? Or is it all of the above? Regardless of the process or decisions or motivations, what we get is outcomes. And we should all focus more on outcomes and less on the politics and negativity surrounding infill development. We can’t be getting into regulation of personal taste and we don’t need layers of design review red tape. Just more red brick.

Spending money in the right places ?

One of the tragedies of building housing is the inverted incentive structure. It leads to costs being cut, or, more likely, investments not made in the right place and time, when they are not only way less expensive but also possible. Opportunities that can’t be reverse engineered without a Time Machine. Unfortunately, the builder, likely isn’t the beneficiary of the investment and is not inclined to do it without reimbursement for the effort, time and cost of capital. As the builder do you really want to put an extra $3000 into an invisible upgrade? If you are working on slim margins, you’d have to do $30000 in successful work to earn that 10%, this makes the 3k hit to the budget actually require you to 30k of business to fund it. In other words, as benevolent construction volunteer you are giving a 30k upgrade of your value that you work hard to create, to the owner for free, at your personal cost. My view is most builders are going to be extremely reluctant to enter into this transaction. And many home owners are equally not likely to want to fund the type of improvements I view as most essential. So I do it anyway. In my view reducing air leakage and humidity in winter into the attic and wall cavities is one of the best places to spend money, for many reasons we won’t go into here. Nobody ever asks anyone to justify luxury cosmetic upgrades, like fancy stone countertops. But what about a drafty house in winter?

Random musings on home building and innovation

I was browsing the progress at my site (this is a euphemism for me clearing out trash, debris and dust in Rubbermaid bin sized loads) on a regular basis over the past month. A few of these involved my friendly helper assisting with the heavy volume and lifting in managing the chaos and dust and depositing it into our dump trailer, final destination Alcop waste station. This rather mindless toil was a good opportunity to appreciate the skills of ‘my boys’ and their handiwork, plus ponder the dearth of innovation in our tactics and approach to our overlapping vocations. So much of what we do is either ‘wet set’ or ‘applied in connected components’ it really demands skilled hands and a large wood framed work space. It doesn’t lend itself to modularity, factory prep, or panelized delivery. The custom, one off nature of these builds means there is no scale or potential for scale. The homes are built more like a custom vehicle restoration than an automobile factory producing huge numbers of identical cars. For this reason, our costs tend to be higher than we’d wish them to be, as we have to fund the labour necessary to install on site all the structure and mechanical systems. Frequently we struggle with planning on paper how we want to install some of these systems, only to have the trades show up later and completely alter the install, because their profound knowledge of the trade is much greater than our paper understanding of what goes where. Even involving the trades up front in pre permitting value engineering and design workshops has proven to be rather feckless in many instances. We’ve had to adjust our mindset to let go of some preconceived notions of how jobs will be done, not without some foul language directed at our boys when we don’t get what we wish. Overall, the compromises we have made tend to work out and we all emerge as winners, as in the homes get built well, and function through occupancy in all types of weather.

I think you will not encounter a group that as a whole is more set in its ways than builders and their long term trades. Time and repetition filter the trades into operating within a certain window and beyond this they won’t adjust their practices. Often it is better not to struggle against someone with a dozen years of experience in installation of these systems, because they know everything, can predict every outcome, and know so many steps in advance what will happen, more than I do. They don’t need to adapt they need to finish the job and move on. For these reasons I don’t see much near term horizon where major changes will be viable in how we build. I don’t see innovation in how to execute these infill projects. They are hard to do well, and don’t get much easier over time. They can get more fun only because the guys are so good they take away some of the brain pain of running the project. Despite the quality of the crew the work takes seemingly forever. I’d prefer not to be stuck at the site for eight months to finish a house. I wish to snap my fingers and see immediate progress. The time from digging the hole to the drywall phase is particularly difficult, exposed, risky and chaotic. Little innovation seems likely to make this quicker or easier. Despite this, production of these homes can be rewarding, and at this point we have such a niche that it is risky to not continue to repeat proven practices, some of which have tens of thousands of hours of evidence that our techniques lead to success.

All of this random information seems to suggest I’m going to continue to do what I’m doing and resist all change, as change likely will cost more, take longer, and result in worse outcomes. Thats a lose lose. Process improvements are like hair splitting micro details, the details themselves are convoluted and complex to explain. Instinct and knee jerk reaction greatly impacts our openness to change. We know that the natural order of the project is chaotic and disorganized and a mental price needs to be paid to bring order and quality to the site. We have such a finely honed instinct of risk and cost that comes from losing control of the budget so many times we have a jaundiced view of newness and hype. We don’t even like to meet new people except in rare instances because we have a good group that functions as a team. Deviation from proven performers or product could mean grass isn’t greener. There is 50 years of logic behind our order of operations - we inherited how we do what we do from builders we never met, as did the journeymen from their teachers. Talk about resilience and resistant to change!

Big moves create equivalent antagonism

We’ve seen a rise in anti-development sentiment. This is both blowback from the rcg rezoning (I support and continue to support allowing townhouses in infill areas), and a level of dislike of members of what now appears to be a lame duck council with many declining to run in the fall election. You have to feel some sympathy for the people on the council, regardless of what you think of their policies. The replies on anything they do or say or post on any media is incredibly harsh and nasty. Even the dislike within the council itself continuously printed in the newspaper must be hard to operate in for the individuals.

All this points to changes in the coming year to restrict the most needed types of housing (anything other than single homes and semi detached homes and large condo towers). It is the homes in between semi detached and mid rise apartments (with underground parking and elevators) that I view as most needed and increasingly hardest to permit and pencil. This middle zone gets harder to build and more complex and fee heavy, almost like a compounding red tape to stifle supply. The precarious project really is subject to that saying ‘straw that broke the camels back’ regarding how easy it is to tip a proforma into ‘no go’ territory.

All of this is unfolding as the new, much needed zoning bylaw is being drafted and unveiled. This is a case where politics and department policies may butt heads. You’ve got to assume the technocrats take direction from the politicians, sort of like the recent local area plan update voting debacle. A small shift in council numbers lead directly to that lost vote. The next council will have at least 5 empty seats to fill from resignations, and some incumbents that re-run will lose. You could have 2/3 of the makeup be a shakeup, including the top seat. The next council perspective on townhomes seems primed to shift substantially.

And all of this is happening as larger companies bundle parcels together. These costly assemblies are compliant with land use policy now, but will this change? The homes on these lots are very old and essentially obsolete. They seem to be bought at high prices justified only by adding significant density. This density is most offensive to those living closest and inclined to be active in opposing the projects. What is the end game here? Difficult and risky investment decisions, unpredictable outcomes, lots of winners and losers. Some design companies and builders really pushing the limit of what is permissible doesn’t help either. A wide range of building and architectural quality is observable - not all good. This is ammunition for the anti-development faction to use. Any economic slowdown or trade battle or whatever color of swan appears would mean a lot of broken projects.

Link to my Substack post on inflation impacts for builders and how to manage this problem

https://infillvaluecreation.substack.com/p/operating-in-an-era-of-currency-devaluation?r=i6cqy

Strange market info

The guys at Newinfills published some interesting market info. As is the norm over the past four years, inner city townhouse sales via mls are terribly low at just 52 units 2024. This contrasts with the appearance of inner city townhouse building seemingly everywhere in quantities vast enough it would be hard to count. While most supply is purpose built rental, perhaps in a catchup quantity now to create a market glut, the 52 sales just represents what hit the actual market. I’m sure some at least pre-sold or sold off market so the mls data is quite void of context. The mls data seems incomplete at best. The crazy thing is if the city would just hurry up and approve some more projects, even one additional completed and sold spec townhouse sold on the mls would represent 10% of the total annual yearly sales! I just can’t comprehend how much the permit times can actually influence units hitting the market. This should be a strong red flag to the city leadership to ‘deal’ with some of its internal divisions that are ‘bad actors’. City of calgary needs a doge!

Time to permit - who’s counting?

Time to permit is a major problem of 2024. Countless anecdotes have been shared of long wait times to get development permits through. The city does post some permit time standards and measurements, but I think these are somewhat misleading, particularly for that troublesome townhouse sector. For each townhouse that does get a permit within the average, there is another builder suffering agonizing waits. To estimate the daily cost of these delays all one must do is calculate the price of the property holding cost / 365. Months of delay implies loss of an entire summer building season, a next level of hardship and loss to the builder. The greatest factor seems to be the time between submission and first and second ‘team review’. The first team review will inevitably require redraft work, resubmission, and this is where it goes really wrong. The second team review appears to lack any priority among the reviewers, as it is at this point a ‘cold file’. The time between resubmission and a renewed three week window for public feedback can stretch an indeterminate length of weeks, or months, adding to the time before the second team review is complete. The hack here would be have the plans so perfect that a second team review isn’t needed and the plan goes right to a decision. I don’t know how often this occurs but it may be possible, within some godlike, bylaw omnipotent drafting sweatshop whipped into goblin mode frenzy of compliance.

Contrast this with a recent single home with basement suite and garage adu application. It was done in seven weeks and the team review contained one tiny labelling change that was insignificant enough it was a 30 second fix. Resubmission did not require a second team review and it was approved the next week into a three week public appeal window. With no legit grounds for appeal it sailed through to permit release. This entire process was a painless two months of which more than half was time for initial public comment (community panel even said it was good) and opportunity to appeal. This makes the single home entire dp process less than just the time between team reviews for a townhouse with just a few more units. Clearly the advantage here is to the single home builder over a townhouse builder, and the total cost is just a fraction of the townhouse set of fees. The permit time is a large cost and risk factor that incentivizes the builder to direct investment where it is best treated. The city needs to make townhouses easier to permit and less of a quagmire of incessant redrafts and edits that don’t make the project any better. Often the second team review will result in capitulation where the builder is so frustrated and has lost so much time he tells the drafter to do ‘whatever it takes to get it passed’. Typically in our first draft we feel we’ve already done that with many compromises inherent in the work.

What the city is unintentionally doing is making plans that a design co gets approved more valuable as they are now ‘proven’ to pass. Copy cut and paste is the result and these plans will be built over and over again. The creative budget is reduced and more money is left to deal with compliance and appeals. In this way the city is pushing design by compliance rather than design approval based on quality. Some odd outcomes will result based on the unintended consequence of too much attention to regulation and too little to quality and livability of the townhouses. We are seeing this in the hgo zone mostly with the stacked flats model of building, less so in rcg with basement suites. I think the worst element may be the number of exterior doors in a stacked 10 unit building (looks like 5 townhouses from the front) with 15 exterior doors needed to be placed at or above grade. It can look really awkward. These buildings would be much better as single stair common entry designs as we used to build back in that coveted mid century era.

Regardless of how this will evolve over time, the single home business is just easier, faster and less risky. Word on the street is many more townhouses are being appealed due to the vindictive anti housing subculture that has emerged from the blanket Rezone process where more individuals want to fight off any building in their community, and discretionary projects (all townhouses) are most easily targeted as they lack the permitted use defensive cover.

There is a new zoning bylaw being drafted, I’m hopeful this will lead to preferred approval for all housing, not just singles. And it can tackle the middle sized project challenge much better than the cumbersome rcg hgo zones do today. There are many initiatives related to this, a new red tape reduction hotline for housing, a plan book of ready made designs that will get fast tracked, and process improvements involving the department and the industry groups. Much of this will be interpreted by the general public as city hall being in the pocket of the caricature of rich developers. Anti housing candidates are already mobilizing for the next municipal election and will likely form a slate to unwind changes to make townhomes easier to permit, while administration is trying to go the other direction to make townhouses more viable. All of this points to plenty of risk and turbulence in the future. Hopefully by then my project will be approved and in the ground and the permitting fiasco a distant memory.

Wanted - someone crazy enough to ruin themselves on a disastrous concept and bail out land seller plus fund a nice commission

Every once in a while you browse the mls and see some ridiculous concept and the associated realtor description with its many inaccuracies and exaggerations. I often wonder if there is someone out there naive and gullible enough to purchase these deals.

More disconnect between supply and demand for the infill builder and buyer

As the calgary market appears to be balancing after a long stretch of hot sales and rising prices, real weakness is showing in some sectors. This is most noticeable in the over $1 million semi detached infill. Due to the escalation of land values, these well known sw and nw infill communities have become very expensive to work in. The main product type is the semi detached on a 50 ft lot. Each old house fated for demolition results in two new units to be sold. Every new builder entering to the market will inevitably build this product, driving up supply to sell and driving demand for the raw land. Buyer unwillingness in the past to pay seven figures for an attached home was significant. Now, the homes need to be sold for well over that sum so the builders can recover their vast input of costly land and labour. Essentially the builders are bringing in large quantities of supply where there is a finite and unlikely to grow buyer pool, driving up months of inventory. In this segment, the months of inventory is kept artificially low as many of the builders only list one of the two new sides as they approach completion. This masks the true number of houses that need to be sold. There are plenty of reasons why the most likely to get built product type is a mismatch to the buyer aspiration, and, given news from city hall, the situation is likely to grow worse. The city is seeking ways to improve and speed up permitting in sprawl communities, this will result in more supply being built in the outer ring road areas. As more supply is available it reduces the cost of new single homes in those greenfield areas and highlights the growing disparity in price between sprawl and infill. As a result the infill semi will drop in a relative value comparison for what those same purchasing dollars can buy farther out (mainly size and space). Since I’ve abandoned the commodified sector of 50 foot lots I don’t have much of a stake in this market, other than i don’t like it, and haven’t liked it for quite a few years. if it becomes a buyers market bloodbath as too much product gets built on land that was bought at too high of a value, I will be glad to have sat out the entire cycle. Adding in basement suites is a recent trend that appears to make financing easier, but it also impacts the livability and quality of living spaces for a family who purchases these homes (all the layouts are functionally identical). All this information basically means is these semi d infill houses are just not a great value anymore. They were originally created as a cost effective new build in established areas where new 4 bed 3 bathroom homes were needed but massive footprints were unnecessary. Now the homes are costing so much there is justification to upgrade further into a detached with a laneway unit, especially given cmhc changes announced this week. Not surprisingly I’ve got one of those ready to start - just waiting on the fell set of permits and perhaps we can dig a basement before Christmas.

City hall revenue problem? Maybe time to rethink how it assesses property

We’ve posted before how efficiently and frequently the staff at city hall are able to issue mid construction re-assessments. Or how adept they are at assessing newly built infill housing at the pinnacle of retail value, like a housewarming gift from city hall to maxed out first time homeowners. Our case study today suggests that assessment algorithm could use a little tweak. My proposition is the tax crew start to mine the publicly available data for those who know the property best - current sellers. Once listed on the mls, these homes reflect the truest value and condition of the property. So lets incorporate that into the tax assessment system and use it as a technique to raise appropriate funds for running the big blue machine downtown.

Much of the errors in current tax practice seem to really benefit the boomer group - the kind that bought cheap and has been comfortably housed for decades, vs the maxed out millenial sneaking into a townhouse or semi detached, or renting. Under taxed property are typically large lots in prime areas, often drastically under assessed. City hall is leaving huge sums on the table, catering to the anti development core group that expect the planning department to mandate scarcity and preserve restrictive land use, while decrying investors as exploitive opportunists harming neighbourhood character. When it comes time to sell, this group shows it has been using the family home as a tax sheltered investment vehicle all along, with mind altering perception of their old home value.

Some of these tax histories appear to even show no tax increase since 2020, despite the massive societal inflation in hard assets and currency devaluation. In real dollars, this example seems to show the tax applied has actually gone down over the last decade.

Why does city hall not review this information and issue a special assessment based on the owners self declaration of value and the one million dollar difference between that and the 2024 final tally? If it can reassess a construction project quarterly, while it is vacant and has no resident using services, surely this is an easier and softer target for raising revenue? Won’t it be a little tricky for an outraged home owner to appeal his assessment when he had just independently valued it in the most public way possible?

what lurks in pre-development 'deals'

We commonly see a land sale on a potential infill development site, it sits for a year and then hits the MLS again, this time advertised with a development permit complete on it. Typically these are listed at a significant premium to the market value of the property, implying a massive uplift just from the partial permitting of a project. Some casual observer may find this a legitimate improvement to the property, more likely it is a copy, cut, paste exercise where an existing design is reused. This could cost anywhere from $5-20k, plus time, but likely is on the lower end of the spectrum. In terms of the broader cost to redevelop the site and purchase the land this could be about 0.5% of the total project. In the view of the seller, a common ask is for $300k over and above the original purchase price. This would represent more than the likely entire gross profit potential for the project, such that if it was sold at the asking price, the actual builder/buyer would have to fund the land, construction, financing, tax, sales cost, and business administration at a loss. I doubt there is a lineup of willing developers with the sophistication to stay in the business of home building who’d jump into a losing deal. From a principled perspective, I avoid these deals, typically the land or designs on it aren’t exactly what I am looking to build, or the deal makes no sense. I view these as distressed sales, after all, if the original plan was to build it, and that has been abandoned, there must be an underlying reason. That reason I believe is most commonly as follows;

the investor lacks the financial means or commitment to the build,

the building partner brought in to build the project has given the investor an estimate and the numbers are too high for it to work

another, better project has come along that has captured the investors attention and funds are needed to pursue it

or, most likely, the investor views selling the project and immediately earning more than the entirety of the likely profit potential of the build is a better outcome that then risk, effort and time to create value in the world via building. So basically the investor wants to dump it yet still capture most or all of the future value of the building project from the buyer.

The first three scenarios demonstrate to me some distress, and dis-inclination to proceed to build. Those investors need to take a haircut to find liquidity on their abandoned deal. The fourth shows a counterparty that is overtly selfish and views their own time and energy as more precious vs those of a potential buyer who should be eager to build a project for free while they walk off with all the profits. Time has the tendency to cure these wounds, and the inflated asking price comes down to reality. At this point, patience, stubbornness and luck all has a role to play in these deals getting sold. Yes the market has possibly run up a fair bit over a year or two, and some appreciation is justified, but the original asking price on this example is just outrageous. A 45 foot wide lot will never be in high demand in a B- neighbourhood, and a smaller footprint will impact the size of the homes to be developed, further limiting upside vs comparable homes on standard sized lots when this build is closer to 1600 square feet of developed area vs the more common 1800 square feet. Finally, I just dont want to reward and incentivize competitors to buy up more land and repeat this process, driving up my cost and lowering my choice of land to purchase from. So count me out as a buyer unless there is real distress demonstrated and value returns to this bad realtor math equation.

Bad business - crazy money for old homes

Who wants to toss $600,000 at old homes on 25 foot wide lots ? I don’t. These present bad business opportunities, thus, basically mean terribly asymmetric bets for the builder. Even though renovated, and show as ‘new-ish’ inside, these bones are 110 years old. These are pre WW1 homes and were built using the resources and technology from that era. I’m surprised they survive as well as they do. These are ancient buildings for wood stick framed homes in a climate with extremely cold winters. Gremlins lurk for the next buyer undoubtedly. I’ve torn down homes 50 years newer than these, and those were nasty wrecks, but often the concrete was solid below the walls. The unknowable viability of these old homes means these are likely asymmetric bets for an end user as well (at nearly $600k), who may stretch his or her finances to buy them and end up heavily indebted with little cash in reserve for repairs, and none of the skills to fix systems that are 80 years older than their owners. Yet these are priced way higher than land value, indicating the homes are retaining considerable value as they age, and older renovation cost is added to today’s price. I’ve torn down homes and felt that raised the property value once the demo was complete. My only comment today is markets change. What will these be worth in another 20 years ? Can’t even guess at the future value or remaining lifespan of a pre WW1 structure.

The growing disconnect between policy and reality in the so called ‘missing middle’

Headlines are attracted to mega policy change but the barriers to actual scaled deployment of more missing middle development are increasing rather than decreasing. In my view the missing middle project is becoming desperately risky for fledgling developers. These types may have plenty of passion and energy for the outcome, but few of the weapons of war needed to win battles. Those most suited to middle success are self performing infill home builders with business continuity, trade relations, equipment such as trailers, tools and machines, and who’ve normalized the order of operations at the job site. They can layer on difficult financing requirement and middle technical challenges, and permit fiascos and massive time waste, while continuing their typical day to day operation such as building single homes and semis, or whatever their bread and butter type predictable source of survival revenue is.

New or aspiring ‘middle’ entrants will have none of this knowledge and ‘can do’ confidence to step up and tackle the middle sized jobs, which are much harder to execute thus much riskier, and likely are busy at their unrelated day job. How to transition to developing middle while undergoing some sort of personal phase change that might mean a bunch of years of hard fought experience in the business?

My reluctance to counsel first time developers to attempt immeasurably hard, slow, risky, brain damaging middle projects rises in lockstep with my own gag reflex staring into the void of my project pipeline. One glaring difference between my own plans vs those of the typical new entrant is I have the land and budget in place without requiring the services of friendly 15% loan to own money lenders. And I still can’t really be successful in the middle as the projects become more awful to permit and the bylaws more intent to ruin viability, regardless of what the happy policies are coming from the mayor. I’ve come to the conclusion that those people really in charge, whoever they are, don’t want middle development. It is a symptom of this era of too much government and too much power in the hands of those who have nothing to do but make operating harder, like an annual ritual, while being personally rewarded with lucrative benefits and compensation without responsibility to actually do anything. The power of the government is strange in the way it manifests as a sadistic nemesis always ratcheting upward its strangulation of project viability. Is there a cabal of brokers that meets somewhere to seek out new and sophisticated tactics to prevent development? How is the government so good at damaging projects while being so inept at operating within its own jurisdiction? Why does the right hand of government seek to harm what the left hand attempts to enable? All of these questions are not likely to be answered and no layer of government held accountable. It may begin to make sense to retreat from any attempt at middle development soon, given the trajectory of dealing with the government. Who is going to deliver this message to aspiring developers?

‘Training’ on how to do infill development

Developer training is a perilous task. The initial project of any new entrant is fraught with execution and financing risk. Attrition will be extreme. Instruction manuals on how to do it are few, or non specific enough to be useful. The key knowledge holders of specific moat protected niche are often loath to share or train new competitors.

Most training opportunities (like seemingly a lot of professional development classes) are expensive and not deep enough to actually achieve what is needed. Or worse they are just thinly disguised as marketing for those that wish to profit from aspiring developers by exaggerating the need for the service they offer. What is really needed are intern positions in a sort of guild. Instead of getting a salary, you’d need a reverse exchange where the intern funds their own involvement. Note the company owners who’d have to run the program value their own time at among the highest in the industry - these are people running eight figure businesses with plenty of time demands to juggle and risk burdens. They don’t need to carry around time consuming trainees.

I’m not sure what the answer is here. I’m posting my own thoughts - for free - on my Substack but it isn’t really sufficient. But it’s free !

I am the idiot who purchased identical land and paid $165000 more

Seems like I am unable to resist the current FOMO when it comes to calgary real estate. Prices have escalated a lot and in a rising market it is easy to convince oneself to jump in with the speculative tide. All the builders, copycat sheep, mindless lemmings, act is if part of the borg collective from startrek. Gotta buy now if I don’t someone else will! This is the sentiment and it makes for silly and irrationally exuberant bids on land. Here is the math, paid $165k more for the same lot on the same street. This was after a period of 40 months from the date both deals were signed. So I’m paying $4125 extra per month for the lot down the street on average for the last three-ish years. That really adds up a lot over time. The increase in price is quite likely more per month than the ability to save for a down payment among those households aspiring to buy. This means housing is getting more out of reach. And the house I got is bad enough it needs immediately rehabbed or torn down. I’m going to tear it down so that means I get to absorb a large carrying cost of the vacant site. Maybe if it continues to increase at $4k a month I can hang on and eventually it won’t cost much to hold by the time we have rebuilt and sold. The other good news is the next lot down the block, also identical, sold for $100k more than I paid. Safety in being part of the herd?

RCG zoning has passed - so what? Gazing beyond the conspiracies, a better future for Calgary

After countless hours of testimony, much of it nasty, brutish, ill formed, and disrespectful, Council approved the plan to change the basic land use that formerly allowed only single homes and/or semi detached homes, to continue to include those types, plus townhouses. This means that first donut around the core, much of it previously untouchable, can now be developed into housing decided much more by market forces, and much less by obsolete and arbitrary regulatory restriction. This unwinds a fair bit of that post war garden suburb planning doctrine that defined Calgary inner city, for basically all of our collective memory and experience living as Calgarians. And what does that first donut ring include? A lot of coveted and highly valued land, some of which is currently occupied by 1000 square foot bungalows on 6000 square foot plots built in the 1950’s. And what are the consequences of this likely to be? We can explore some key themes below;

land value hysterics - much ado about nothing here. land value uplift has already been priced into the market, the beneficiaries, long term property owners. In other words, the establishment. Pity the poor builders that have to buy in now to find a site to build on, they just enrich the seller and marginalize their own business. Never before have we witnessed a riskier time to buy land to develop.

process savings - the builder will no longer need to navigate a lengthy and costly process to change the land use from Rc2 or Rc1 to Rcg, basically this could chop some fees and holding costs off of many future projects. This is a good thing because little societal value was gained by the rezoning process, and it involved too much time waiting for a planning commission review, and a council meeting slot to have the full council vote on a tiny townhouse vote.

More product to sell that is smaller and more economical than the semi detached home market - definitions of affordability were flung like dung at the hearing, but the basic math is incontestable. townhouses cost much less than semi detached homes, and a fraction of new detached infill. New townhouses must be measured against what would otherwise be built. For example, new townhouse can easily be built and sold for 5-6-700k, depending on location. In an Rc1 area, the like for like replacement that was the only viable path to new housing would require a new build to sit on a land cost from 7-900k (or even vastly more - could be two million), making the finish product starting price around 1.5 million for a basic new single home.

Suites will continue to be built as the only truly affordable product offering not taxpayer funded - the suites appear to be the most contentious issue, because, when linked to a new townhouse, would not require a new parking stall. Many councillors and the general public attacked the existence of the suite, while decrying need for affordable housing. It does appear the only way the market can build affordable housing is to include suites within the townhouse. This is a good thing as a pressure release valve in a time of housing scarcity.

allowing a suite and a laneway house on one plot seems like a good and easily digestible idea to most people in the community - while nice to have, this will have almost no meaningful supply impact when a few laneway homes are added to new detached home builds in prestige communities.

it appears the planning staff in the key positions of influence over policy are on board and largely, if not unanimously, reject single home only replacement rules. I found the staff presentations and arguments compelling, others less so. This appears to be a memorable ‘changing of the guard’ moment in Calgary. There was also a large age/voting preference discrepancy on council.

Where are the opportunities? - my thoughts are that the formerly forebidden zones, the Rc1 areas, with the biggest lots and smallest old homes, offer the best opportunities. The market has yet to figure out the implications of increased development potential, after some expirementation, someone will guinea pig a new approach and it will catch on as the builders are inherent copycats. This will occur only at the pace that willing sellers enable it to.

little change in the Rc2 areas - these lands were already priced as if RCG was a foregone conclusion, because it was. I don’t see much added buying pressure here and most prices are already too high to even justify townhouse projects today, given the speculative land craze that has hit the market. if anything we could see small land value correction, this would be welcome.

As time passes, I view the new RCG zoning as a means of introducing some new population into areas that have declined via shrinkage in family size, and some new housing stock variety where previously only mansion replacement was permissible. Both of these features are good for society. Neither of these features will mean some sort of character assassination of established communities. If anything, those enclaves protected by the ‘never to expire restricted covenants’ will mostly benefit, as suddenly, single house only regulations are more scarce than townhouse friendly regulation. This is also a good thing. As the new rules are digested by the market, I am optimistic and grateful to see leadership shown by the Mayor and much of Council to modernize our infill development rules.

This chart was floating around X during the hearing. I found it to be quite a convincing display of the disparity in price of new single homes vs new townhouses. Note the semi detached market data is not shown, this is by intent to present both ends of the spectrum of new home cost in the most simple manner. Also note, there are few townhouse values shown over 800k, I am assuming this is based on assessed tax roll, and there are very few new single houses valued below 800k. If there was another chart showing semi detached values, 90% of the values would be cluster today from 800-999k. Is there a compelling argument against townhouses when viewed in this context?

"Nodes and Corridors" a mantra not worth repeating in the RCG blanket zoning debate

Who’d have thought, the unsexy phrase, “nodes and corridors” would become a slogan of those wishing to express displeasure at the concept of introducing townhouses into the low density communities closest to downtown. The phrase is both planning jargon, yet familiar, so appears to pass a sniff test for knee-jerk rejection of townhouse building by offering a technocrat sounding solution. If only we’d pursue a “nodes and corridors” policy, all will be well, and the city can simply move on to more important matters, putting to rest this divisive blanket rcg zoning hearing debacle.

Upon closer examination, the phrase simply falls apart as a means of legit policy defence against townhousing. Look at any local area plan, these take the “nodes” like transit hubs, and the adjacent zoning policy begins where townhouse zoning ends. The “nodes” are already nominated for taller residential and mixed use buildings. Same with “corridors” where the city has launched main streets initiatives, townhouses are not found on these major thoroughfares. Instead, where the city has decided to initiate land use changes, it, not surprisingly, nominates areas of land that can really move the needle on creating meaningful supply. In a city this large, there is no theoretical limit for building condos. Vast land exists already capable of housing thousands of units, for example, just the surface lots outside of box stores, strip malls, and office towers offer major density potential.

The problem with condo density, it is all the wrong product. One and two bed units are in ample supply, what is needed is family sized housing, at a lower cost. This starts with townhouses, wood framed, grade oriented, near amenities, in all the usual inner city communities. Simply building condos does create density, but it has no impact on filling that missing middle between a small condo and a costly, semi detached, new infill home. This is the space the townhouse fills, yet attracts so much angst than sporadically built condo towers.

Even worse, “nodes and corridors” represents a straw man upon which to hang the newfound blended overall density of a community. If that abandoned gas station on the periphery can be replaced with a tower, one can argue that the entire community has now added 100 units. Thus, over the entirety of the community, it can raise the average to an acceptable level, that the cherished, quiet streets, filled only with single homes, can remain frozen in amber, and opposition to townhouses is morally justifiable, after all just look at what strides the progressive group has made to welcome density. And of course, any community leader can always find a suitable, decrepit, abandoned department store to nominate for density. Those areas have been written off since the establishment of the community, and are only now worthy spots to have other people live because the location is on the outskirts and its development poses no cost to the detached home owner. As if, somehow, all the future residents of the area will gladly move in to that turnpike adjacent tower, grateful to the community nearby for its sacrifice of providing a place of sanctuary.

Worse still, the “nodes and corridors” approach is just spending someone elses investment capital without bothering to notify them. It assumes that those with the capital are incapable of discernment among available development opportunities. Let me suggest the holders of ‘smart money’ are very experienced in how to best deploy their capital to a long and risky development. Perhaps that gas station turnpike spot isn’t coveted enough to incent a developer to invest tens of million of dollars in a grade C location or a contaminated brownfield.

One common theme in my townhouse building experience has been to find great locations inside the community where people will actually aspire to live. Once my building is complete, I want to actually be able to fill it. Sadly, “nodes and corridors” are the places I avoid when deploying my scarce investment cash. To me “nodes and corridors” is a mantra that is only useful as guidance on how not to make mistakes in townhouse building.

The RCG rezoning public hearing - reflections from midway

The unbelievably long marathon of a hearing continues. As I type this on Friday evening, we are at panel 83 of what appears to be over 170 groups of public commenters. There has been no shortage of craziness from the general public. A vast spectrum of opinions have been brought forth, some completely incompatible with mainstream mores of decency and sanity. The final vote, if it happens, should be next Saturday, May 4th? I will list a few top comments;

RCG is creating system of feudal landowners (this was directed at developers such as me, I am now a fuedal landlord, hoorah!)

RCG is a tool of the world economic forum to introduce an authoritarian marxism, Klaus Schwab is the ringleader of this globalist conspiracy, you will be happy and own nothing.

R1 zoning is a form of warranty provided by the city to home buyers (of course nobody paid any warranty premium or is willing to turn over profits from appreciation to the city to compensate it for servicing the warranty).

General consensus we need density, however, this is always followed by the big ‘BUT’

city communications staff guilty of at best deception and at worst fabrication and misrepresentation

current council is the worst in history of city

I think the mayor is a borderline saint for handling this hearing (actually nobody said this, it was from me).

the post secondary students are pissed off, I dont think anybody really cares though

home owners feel like their home value is under attack, value is confiscated by the city.

majority of presenters claim the city infrastructure is inadequate, nobody asked the city staff engineers though, they come to this conclusion on their own.

vacant city lands will solve our housing problem. everyone thinks this except the city.

the pace of allowing townhouse building is much to fast - everyone agrees with this except the builders who have to pay for costly, pointless delays.

parking, more parking, and some more parking.

sprawl is demanded. we need only single homes to solve our affordability problem.

claims about repurposing office towers for housing, the people who make this comment are willing to invest $0 in these ventures, but grateful ‘somebody else’ can be voluntold to do it.

developers cannot be trusted (I agree, we change investment decisions faster than the wind can blow).

council is ‘taking away choice’ by adding rcg as part of a menu of possible housing forms. I still dont see how you can take away choice by adding choice, or how protected r1 zoning doesnt take away more choice than adding more housing options.

I think we have heard every possible comment more than 100 x on repeat.

too many garbage cans. existing owners can behave badly with garbage cans, but the new ones certainly should not

one long term resident is stalking the occupants of new garage suites to try and make sure they are living according to his determination of what is acceptable - utter self incrimination of his bad behaviour in front of council and the world - cringe factor high with this character.

one presenter appeared to have been a victim of brainwashing into a cult of guilt and self loathing under the guise of a diversity, equity and inclusion textbook. I was extremely uncomfortable for her and fear she may need counselling. I hope she’s ok.

endless tales of deprivation, poverty and distress were regaled to council. awful stuff.

up zoning will not create affordable housing - of course, nobody is complaining the single house mansion market is too expensive. no recognition that new townhouses will create vacancy of depreciated and lower cost units that is currently not possible due to shortage of supply.

more parking.

'Freedom' - the RCG blanket rezoning culture war in Calgary

I recently heard the accusation that city led RCG rezoning to allow townhouse development is actually an attack on individual freedom. Initially I was confused, I assumed, wrongly, the deregulation, the loosening of restrictive rules on land use, is enhancement of personal freedom. RCG zoning increases property rights, offers new investment options, and enables market control of development rather than obsolete and dated rules enforced by a central authority. I am incorrect, based on this vocal cohort, ‘freedom’ means something different. Are we even speaking the same language? Am I now onside with a marxist fascist regime at city hall? Let’s explore below this topic further.

In our helpful spreadsheet, we examine the outcome of RCG zoning on individuals and communities. The definition of what freedom is appears based on perspective, and position. For those who dislike the townhouse model, allowing townhouses is a war on their property rights, community character, streets empty of cars, and enables the evil developer access to exploit their tranquil enclave. What this really distills to, is those who oppose the RCG zoning value their freedom to control others, rather than the freedom of others to control their own property. I dont think you can have ‘freedom’to control others, this interpretation means that the ‘others’ have no freedom. At some point all of us will be in either camp 1 - want to control others, or camp 2 - dont want others to control us. My default, I’d rather not be controlled by others, that exceeds my desire to control other property owners.

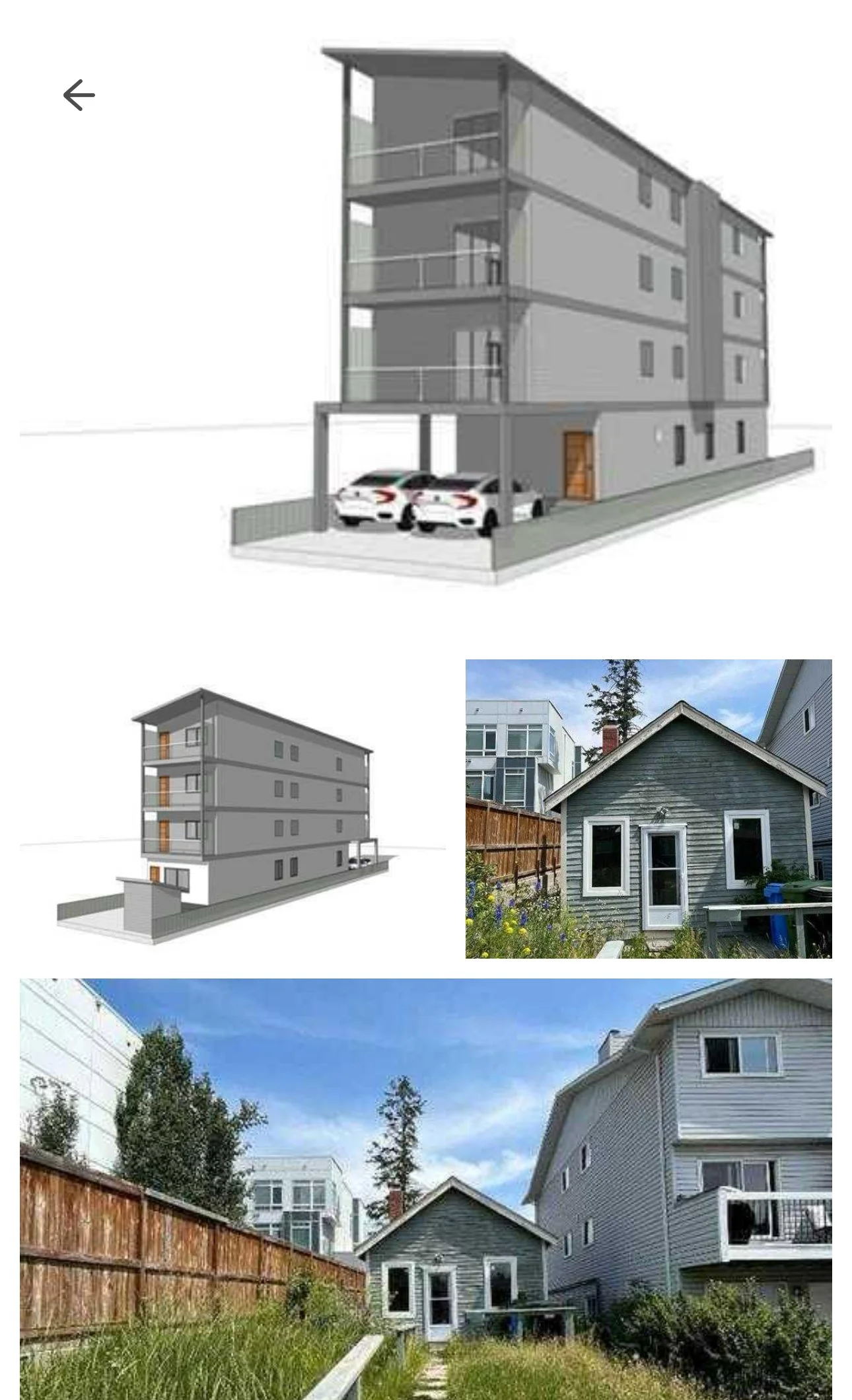

Builders association awards livebridgeland.com best in category

We were greatly honoured to accept the best in townhouse category award from the Calgary Inner City Builders Association at the gala award event in March 2024. Each of these builds consumes us as the developer, for a year of planning, and a second year of hard work managing the site, plus all of the essential trades and suppliers contribute greatly to our success. The list of notable wins involved in the execution of this build is lengthy, and I won’t reprint them here, but major milestones and happy moments were substantial, balancing out some of the challenges and hardships. As rcg type townhouse development has really entered the public spotlight in 2024, hopefully the livebridgeland project can highlight the meaningful contribution good development makes in core inner city communities. With a couple more townhouse projects on the drawing board, and one in permitting now, I hope to carry forward some townhouse building momentum into the balance of the year.